IN PROGRESS -

HEATWAVE Trail Running Shoe

// Exploring ventilation, repairability, and novel cushioning

A footwear project focused on blending the rebound of a carbon plate and cushion of a wave structure using the same carbon piece in a segmented form factor that encourages adaptability on rough terrain.

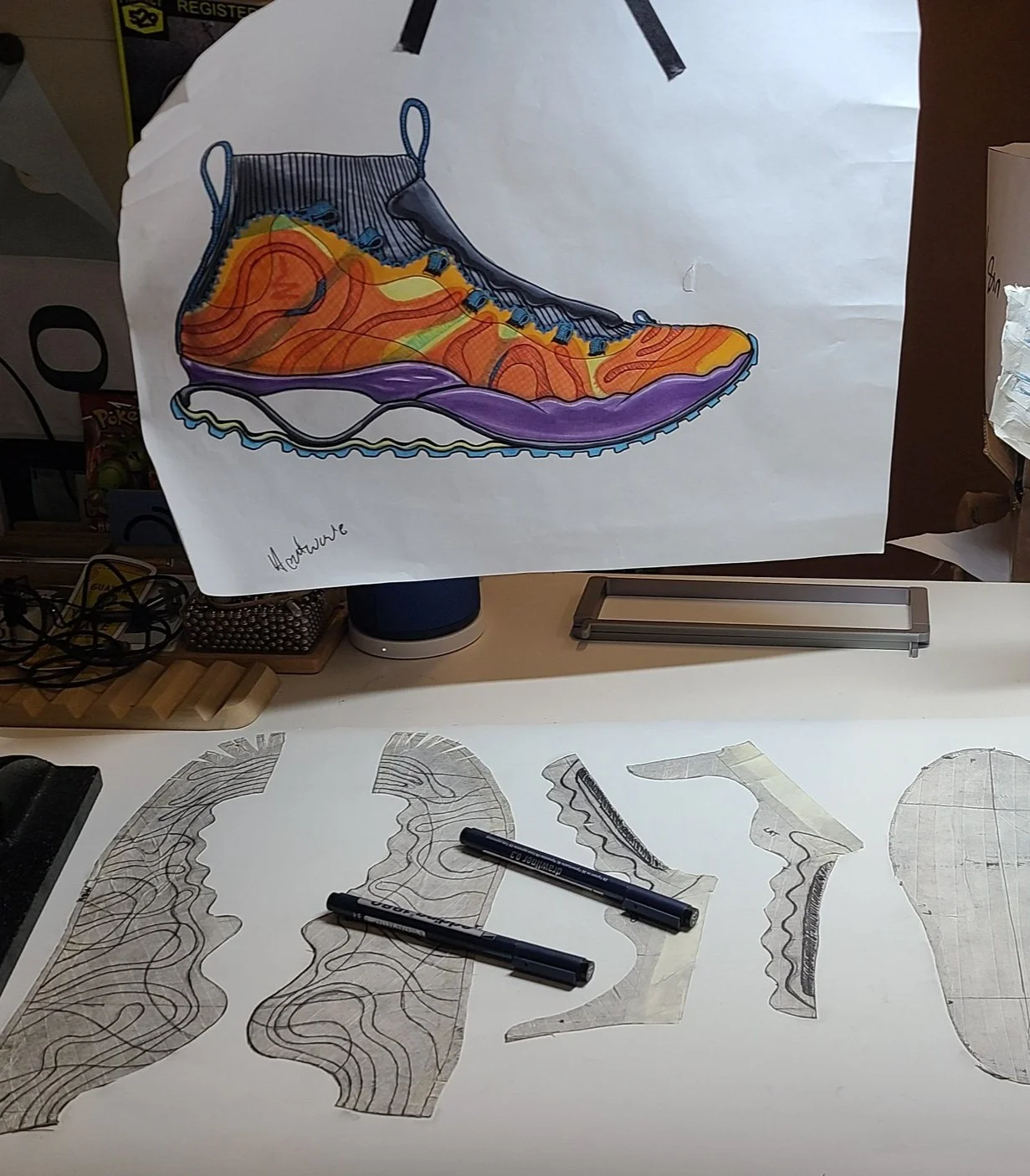

Hacked Brooks Caldera prototype shoe for technology testing collaged with renders of the midsole

Early sketches exploring the cushion system

Testing the prototype on a treadmill. The test athlete said initial cushioning was firmer, with better energy transfer throughout their stride, culminating in a more explosive toe-off.

Upper concepts for use with the Surfboard midsole cushioning system

FINAL CONCEPT DIRECTION

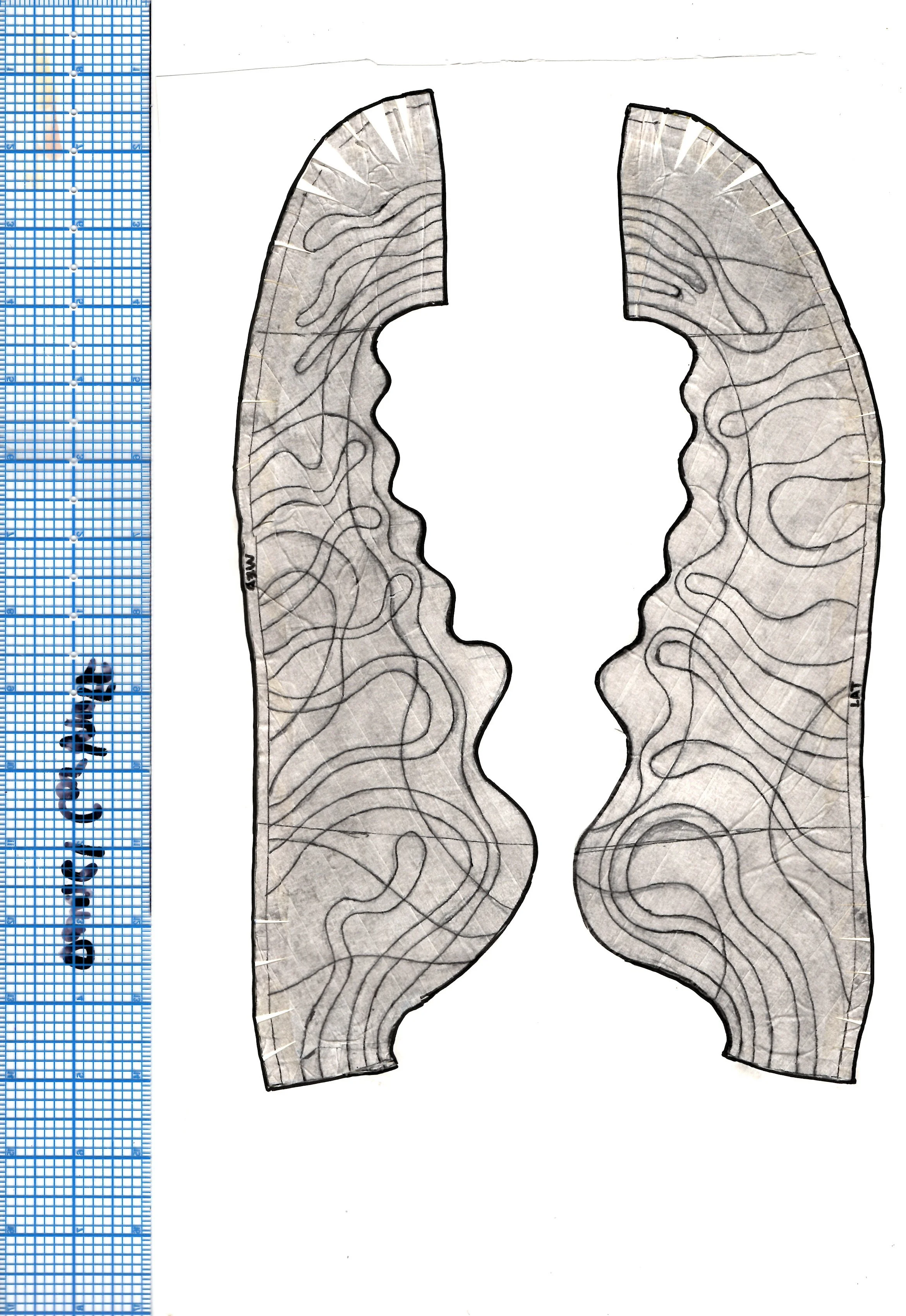

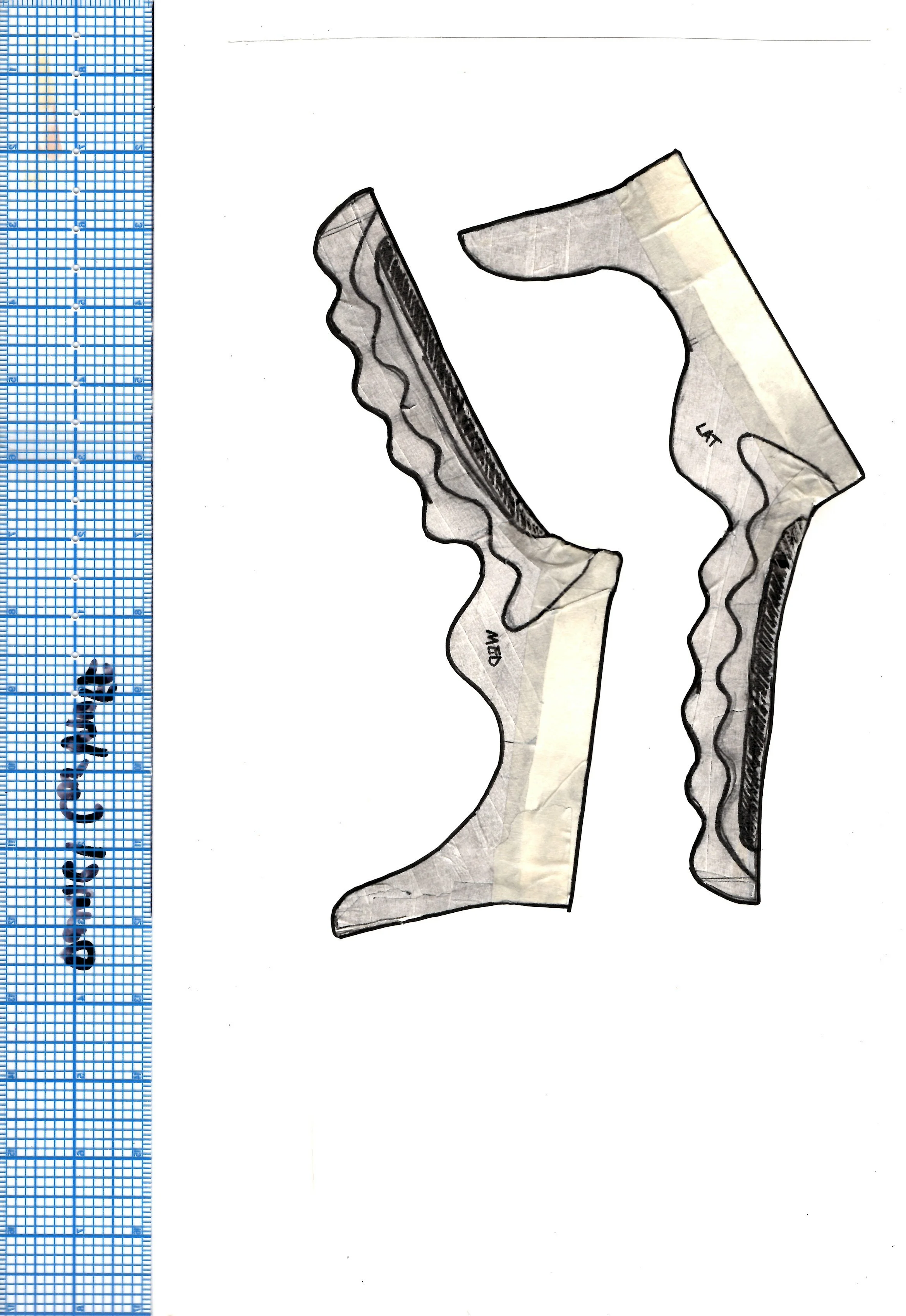

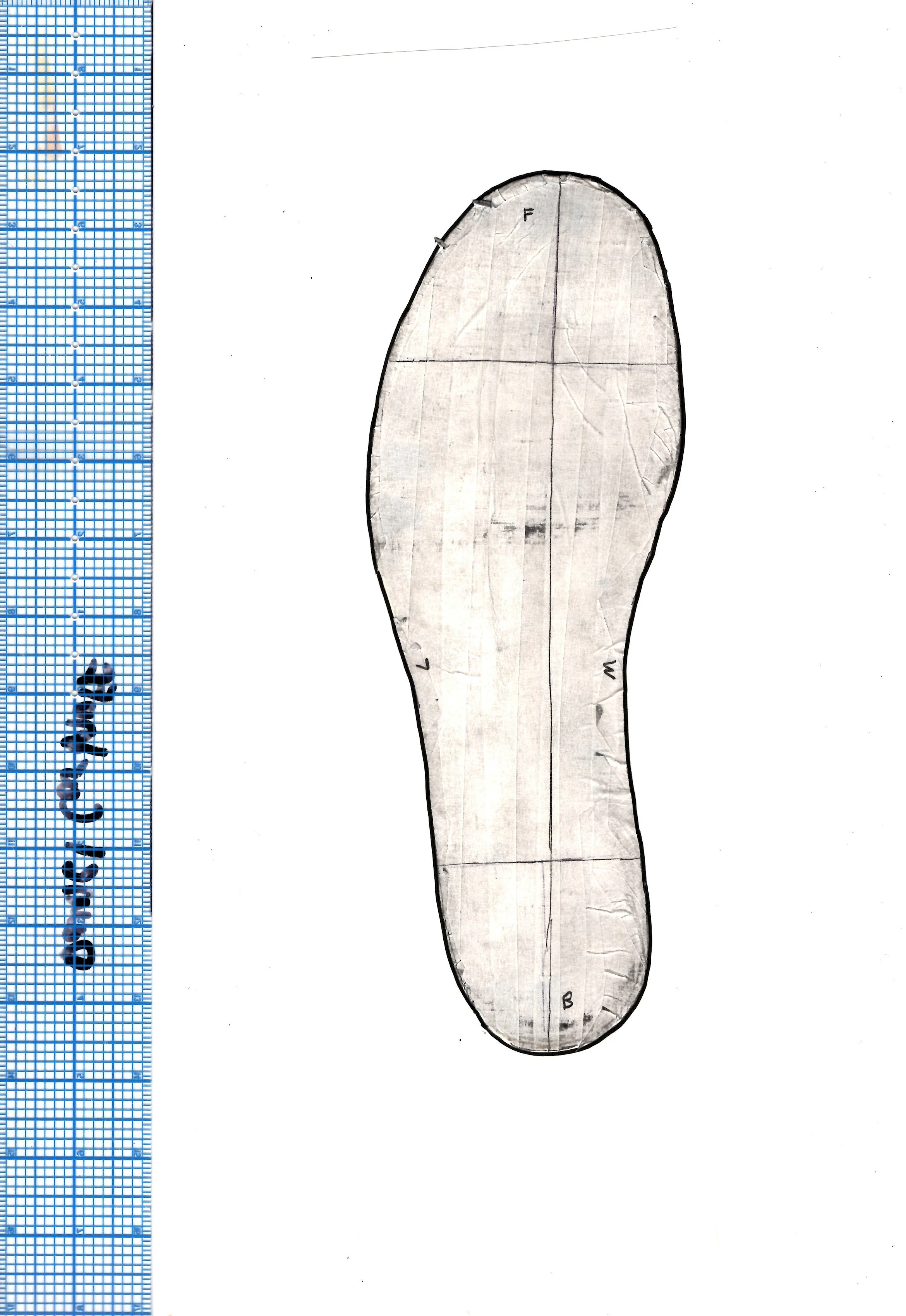

UPPER CREATION PROCESS

The Heatwave logo and all upper patterns were further developed and refined in Rhino based on the tape pieces from my last.

Creating the upper involved carefully ordered laser cutting of each material, initial bonding with an iron, and final bonding with a heat press. Cords under the heat laminated material were threaded through pre-cut holes before bonding. The tongue had to be made twice, as I needed to add more material to give enough space for it to be sewn to the rest of the upper. Lace loop tabs were hand cut and sewn to the reinforced top of the upper, and extra padding was hand cut and sewn on top of the tongue. Seams were finished with webbing and seam tape. The upper was then sewn together on a Strobel machine. Each material, its shape, and where it is placed is a strategic decision driven by comfort and performance.

A Dyneema patch kit was created to repair the upper after wear and tear by using the waste material generated during upper pattern cutting.

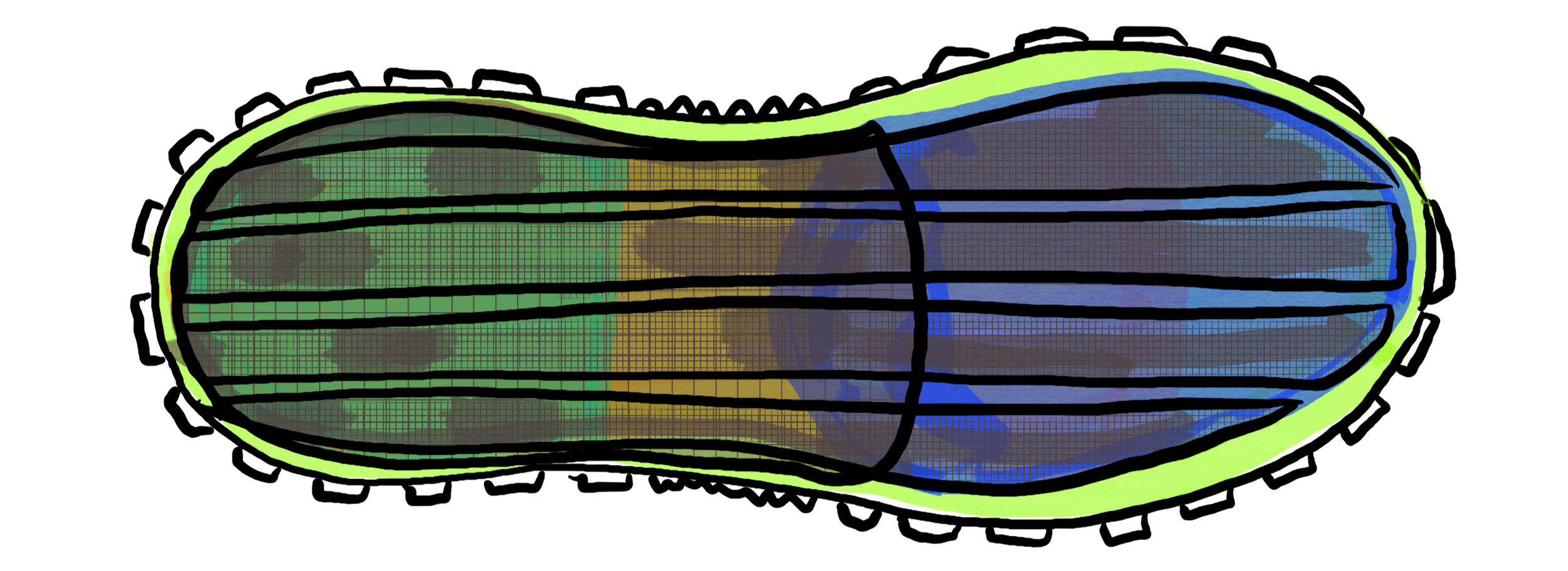

The midsole, cushioning system, and outsole were all designed on Rhino in separate parts for 3D printing. Due to time constraints for this specific project, I decided to initially render only the midsole and outsole portion and photoshop it onto photos of the prototype upper. I have since printed the whole assembly and will be gluing everything together soon for testing.